Introduction

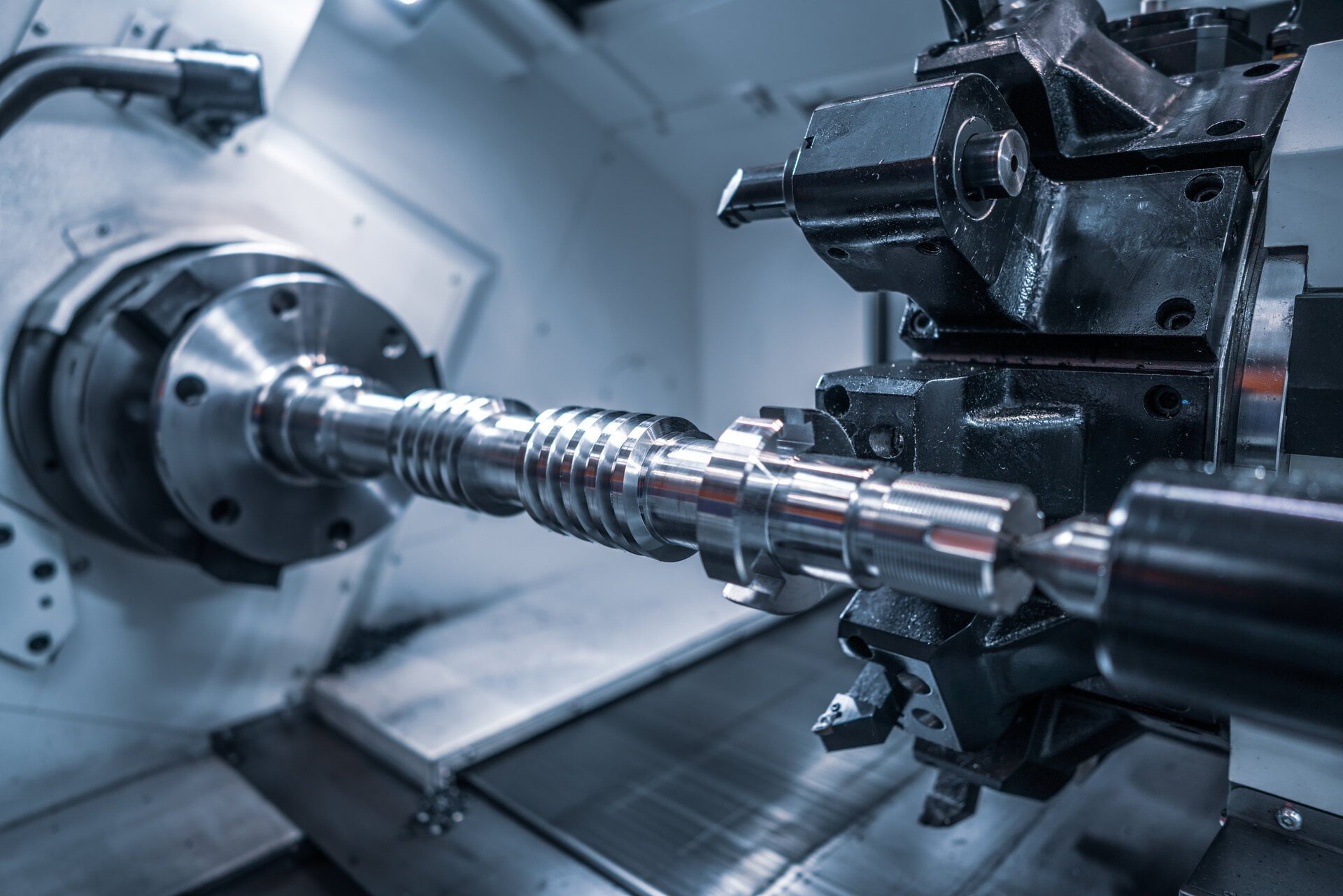

CNC turning is a highly efficient and accurate method of manufacturing custom big parts. The process involves the use of a computer-controlled lathe to cut and shape materials to precise specifications. CNC turning is an essential part of modern manufacturing, enabling manufacturers to produce high-quality, complex parts in large volumes with minimal waste. In this article, we’ll explore the benefits of CNC turning for custom big parts manufacturing.

Precision and Accuracy

One of the key benefits of CNC turning is precision and accuracy. The computer-controlled lathe can make highly accurate cuts and shapes, with tolerances as tight as 0.001 inches. This level of precision is essential for producing high-quality, custom big parts that meet the exact specifications required by customers.

Efficiency and Productivity

CNC turning is also highly efficient and productive. The computer-controlled lathe can work around the clock, without the need for breaks or rest periods. This means that manufacturers can produce large volumes of custom big parts quickly and efficiently, without sacrificing quality or accuracy. CNC turning also reduces the need for manual labor, which can reduce production costs and lead times.

Flexibility and Customization

CNC turning is highly flexible and customizable, allowing manufacturers to produce custom big parts in a wide range of materials, shapes, and sizes. The computer-controlled lathe can be programmed to produce parts with complex shapes and contours, making it possible to create unique, one-of-a-kind parts for specific applications. CNC turning can also be used to produce parts in a variety of materials, including metals, plastics, and composites.

Reduced Waste and Cost Savings

CNC turning can help reduce waste and save costs in several ways. The computer-controlled lathe can optimize the use of materials, reducing waste and minimizing the need for additional machining or finishing processes. CNC turning can also help reduce labor costs, as the process is highly automated and requires minimal human intervention. Additionally, CNC turning can help reduce the need for tooling, as the computer-controlled lathe can switch between different cutting tools automatically, reducing setup times and costs.

Quality and Consistency

CNC turning is highly reliable and consistent, ensuring that each part produced meets the same high standards of quality and accuracy. The computer-controlled lathe can maintain precise cutting speeds and feeds, ensuring that each cut is made to the same depth and at the same angle. This level of consistency is essential for ensuring that each custom big part produced meets the same high standards of quality and reliability.

Applications of CNC Turning for Custom Big Parts

CNC turning is commonly used in the production of custom big parts for various industries, including aerospace, automotive, medical, and defense. For instance, in the aerospace industry, CNC turning is used to produce critical components such as turbine blades, engine parts, and landing gear components. In the automotive industry, CNC turning is used to produce engine components, suspension parts, and transmission components. In the medical industry, CNC turning is used to produce surgical instruments, prosthetic implants, and medical devices. CNC turning is also used in the defense industry to produce components for military vehicles, aircraft, and weapons systems.

Choosing the Right CNC Turning Service Provider

When it comes to custom big parts manufacturing, choosing the right CNC turning service provider is crucial. It’s essential to choose a provider that has the right equipment, expertise, and experience to produce parts that meet the exact specifications required by customers. Here are some key factors to consider when choosing a CNC turning service provider:

Equipment

Make sure the service provider has state-of-the-art CNC turning equipment that can handle custom big parts manufacturing. The equipment should be capable of producing parts with high precision and accuracy and should be able to work with a variety of materials.

Expertise

Choose a service provider with expertise in custom big parts manufacturing. The provider should have a team of experienced engineers and technicians who can design, program, and produce parts that meet the exact specifications required by customers.

Quality Assurance

Make sure the service provider has a robust quality assurance program in place to ensure that each part produced meets the highest standards of quality and accuracy. The provider should have inspection equipment and processes in place to verify that each part meets the required specifications.

Cost and Lead Times

Choose a service provider that offers competitive pricing and lead times. The provider should be able to provide a detailed quote and timeline for each project and should be transparent about any additional costs or fees.

Conclusion

CNC turning is an essential part of modern manufacturing, enabling manufacturers to produce high-quality, complex custom big parts quickly and efficiently. The precision, efficiency, flexibility, and quality of CNC turning make it an ideal choice for producing custom big parts in a wide range of materials, shapes, and sizes. By using CNC turning, manufacturers can reduce waste, save costs, and produce parts with consistent quality and accuracy.