The Role of CAD Drawings, CAM Programming, and Quality Control in Mechanical Engineering in CNC Kovine Gorsek

Introduction

Mechanical engineering is a broad field that involves the design, development, manufacturing, and maintenance of mechanical systems, machines, and components. In today’s digital age, computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies have revolutionized the way mechanical engineers approach the design and manufacturing processes. In addition, quality control plays a crucial role in ensuring that the products and systems meet the required standards and specifications. This article discusses the importance of CAD drawings, CAM programming, and quality control in mechanical engineering.

CAD Drawings in Mechanical Engineering

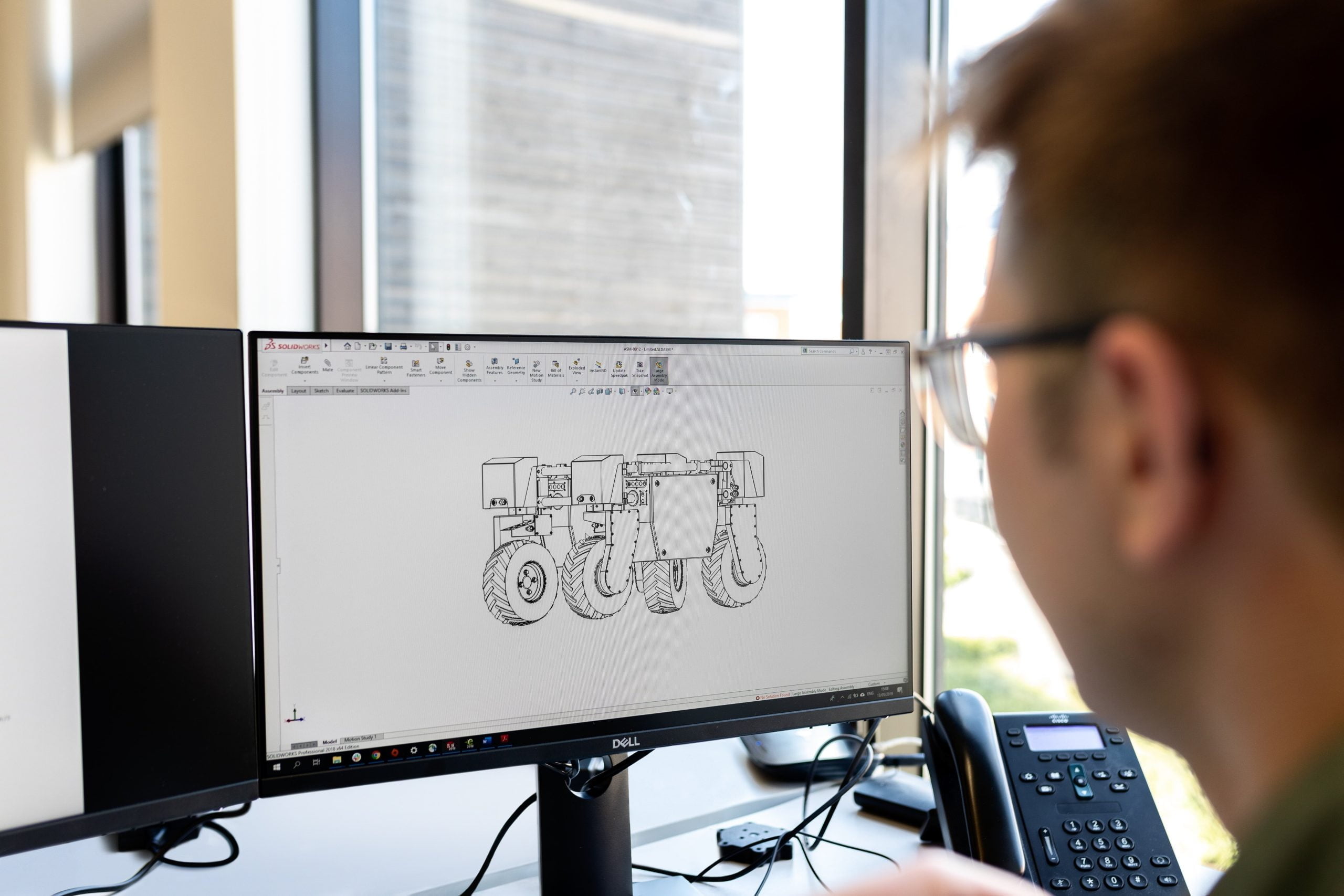

CAD software is a powerful tool that allows mechanical engineers to create, modify, and analyze digital 2D and 3D models of mechanical components and systems. The use of CAD software has numerous benefits, including increased accuracy, faster design iterations, and better visualization of the design. Additionally, CAD software enables mechanical engineers to simulate and analyze the performance of the components and systems, which helps in identifying potential design flaws and optimizing the design for better performance.

The CAD drawings are an essential part of the design process, as they provide a detailed visual representation of the component or system. The CAD drawings can be used to communicate the design intent to other stakeholders, such as manufacturing personnel, suppliers, and customers. The CAD drawings also serve as a reference for the manufacturing process, as they provide precise measurements, tolerances, and other critical design details.

CAM Programming in Mechanical Engineering

CAM programming involves the use of software to generate instructions for machine tools and other manufacturing equipment. The CAM software takes the CAD drawings and converts them into a format that the machine tools can understand. CAM programming is essential in modern manufacturing processes, as it allows for increased precision, reduced lead times, and improved productivity.

CAM programming can be used to create a variety of manufacturing processes, such as milling, turning, drilling, and grinding. The CAM software generates tool paths that guide the machine tools in cutting, shaping, and forming the material into the desired shape. The CAM programming also includes other critical parameters, such as feed rates, spindle speeds, and cutting depths, which are optimized for the specific manufacturing process.

Quality Control in Mechanical Engineering

Quality control is an essential aspect of mechanical engineering, as it ensures that the products and systems meet the required standards and specifications. Quality control involves the use of various tools and techniques to monitor and evaluate the performance of the components and systems. The quality control process starts with the design phase, where the design is optimized for quality and reliability. The quality control process continues throughout the manufacturing process, where various inspection and testing techniques are used to ensure that the components and systems meet the required standards.

Some of the common quality control techniques used in mechanical engineering include visual inspection, dimensional inspection, non-destructive testing, and performance testing. Visual inspection involves the use of visual aids, such as magnifying glasses and microscopes, to inspect the components and systems for defects and anomalies. Dimensional inspection involves the use of precision measuring tools, such as calipers and micrometers, to measure the dimensions and tolerances of the components and systems. Non-destructive testing involves the use of various techniques, such as ultrasonic testing and X-ray inspection, to detect defects and flaws in the components and systems without causing damage. Performance testing involves the use of specialized equipment and software to test the performance and functionality of the components and systems under different operating conditions.

Conclusion

In conclusion, CAD drawings, CAM programming, and quality control play a crucial role in modern mechanical engineering. CAD software enables mechanical engineers to create accurate and detailed digital models of mechanical components and systems, while CAM programming generates instructions for machine tools and other manufacturing equipment. Quality control ensures that the products and systems meet the required standards and specifications through various inspection and testing techniques.

Together, these technologies and processes have revolutionized the way mechanical engineers approach the design and manufacturing processes. The use of CAD software has increased the accuracy and efficiency of the design process, while CAM programming has improved the precision and productivity of the manufacturing process. Quality control has ensured that the products and systems meet the required standards, resulting in higher quality and more reliable products.

In the future, we can expect further advancements in CAD software, CAM programming, and quality control technologies, which will further improve the efficiency, precision, and reliability of mechanical engineering processes. As the world continues to rely on mechanical systems and machines, the role of mechanical engineering and these technologies will only become more critical in meeting the demands of a rapidly evolving world.

If you are looking for a reliable partner to bring your mechanical engineering ideas to life, CNC Kovine Gorsek is committed to providing innovative and high-quality solutions. With a team of experienced professionals and state-of-the-art equipment, we can take your ideas from scratch and turn them into reality. Contact us today to learn more about our services and how we can help you with your next project.